Press-based Pricing

Overview

Here is an e-mail we received from a printer in Connecticut, reflecting real-world conditions in a shop that wasn't built yesterday. It brightened our day to read those heady comments:

"First let me take the opportunity to say how great I think your product is, job well done. I look forward to being able to purchase the complete program for your surprisingly inexpensively stated price of $285 US. Will it be possible to add additional presses? For example, my shop has three single color presses:

•a small format Multi

•a mid-size 17.5 x 22.5

•a larger 23 x 29

I also have a cylinder letterpress used for not only designer-friendly letterpress work but also some simple die-cutting."

Thank you, David. If there is a configuration that will throw a gale-force headwind into Morning Flight's flight plan, this has to be it: Four presses, all single-color, with separate run prices calculated for each. We can safely assume those run prices are all based on Budgeted Hourly Rates. Printing is what printing is - one of the last remaining industries where BHR's still dominate.

Before we tailor the program for David's presses, let's look at what we're up against. When a company installs a new estimating system, the natural tendency is to try to configure that system to the way estimating was done before - to simply automate the manual process. Quick Copy shops generally lean more toward price-book estimating (Counter Price Lists, Crouser Guides, prices governed by what the market will bear), while traditional printers favor press-based, cost-plus methods (Budgeted Hourly Rates, where prices are based on the press used for the job). Morning Flight can accommodate both but is a more "instant" fit for Quick Copy estimators.

Making it work in Connecticut

Let's assume David is comfortable with press-based, cost-plus estimating and just wants to do it quicker, easier, and without paper and pencil. He's using three offset presses, the exact number even the Free Edition includes straight out of the box. We can simply edit those without adding presses, so lets start with that.

![]() From the main menu, click the My Shop button.

From the main menu, click the My Shop button.

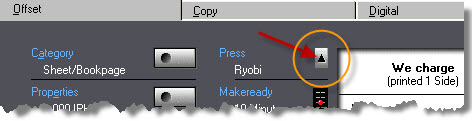

•In the press selection panel, double-click Ryobi 2-Color Offset.

•Press the Colors button and reduce the press configuration from two print heads to one, then match minimum and maximum sheet sizes to David's 17.5 x 22.5" mid-size.

•Close the press update window.

•Do the same for the GTO 4-Color Offset, but with the maximum sheet size set to 23 x 29".

Selecting the right Press for the Job

Matching Morning Flight's built-in presses to the Connecticut shop's profile is only half the solution. What David still needs is the ability to override Morning Flight's automatic press selection and hand-pick any press when making quotes or entering orders. Fortunately, that ability comes as standard equipment in all paid versions, from the Passport Edition on up.

One final point: Morning Flight is product-centric at heart. Before you convert to purely press-based estimating, spend some time evaluating the program's standard pricing model. It could easily be the better choice for most of your printing. Don't forget, you can always select one pricing method over the other at runtime.

The Case against Press-based Estimating

Leaving aside the merits of market-based versus cost-plus estimating, here is what I'm absolutely convinced of: When people go to buy grass seed, it's not the seed they care about. What they care about is their grass.

Printers love to show off their new acquisitions ... and buyers couldn't be more indifferent. Need proof? See if you can remember the last time you took your car in for service, then asked which machine they performed the tune-up on. Never happens! In today's "hurry-up" world, your customers have neither the time nor the curiosity to be impressed by that fancy new inkenspritzer you ran their letterheads on. They'll look right past it. What matters to them are the results delivered to their office. And they'll get vocal when a $100 letterhead you ran last month on a Multi suddenly costs $150 coming off the Heidelberg because the Multi was out of commission. Once you agree with that, the product-centric ways of Morning Flight will look like a very good fit.

Looking to the future, here is something else we need to consider. Some day soon, your customers will expect to find prices on your website 24/7, and when that day arrives, the press you ultimately run the job on is no longer a factor. That will leave the product, not the press, as the price maker. Estimates coming off the internet will by nature revolve around the product, and Morning Flight is just ahead of the curve.

Custom, case-by-case pricing will always have a place in large printing firms. No one with any sense would use a price list, or even a pushbutton computer estimating program like Morning Flight, to quote a million+ run. But in smaller shops, consistent pricing is the key to keeping customers (and shop owners) happy, and that's where Morning Flight's product-based pricing strategy excels.

What about the Letterpress ...

Ah, yes, the letterpress. We still need to find a corner for that "cylinder letterpress used for designer-friendly letterpress work." In the Silver, Pixelblitz, and Gold Editions (as well as the new Skypricer), letterpress can be quoted as merchandise. The die-cutting part, of course, can be treated as postpress.

See also